Sustainable Packaging

Eco-Friendly Innovation: Our Commitment to Sustainable Packaging

At ENOUGH., our commitment to sustainability goes beyond our skincare formulas; it extends to our packaging as well. Our upcycling ethos ensures that every aspect of our product, from contents to container, is designed to minimise environmental impact and champion eco-friendly practices.

Our Upcycled Fabric Packaging

All ENOUGH. upcycled bags and pouches are handmade from rescued clothing and high-end textile waste by Vivacious Eco Vixon.

Through her partnerships with ethical NGOs and NPO sewing programmes, including initiatives supporting women from adverse backgrounds and GBV shelters, skilled women artisans transform discarded materials into purposeful, limited-edition packaging.

Reclaimed Fabric

Made from high-end fabric waste that would otherwise end up in landfill. Each piece gives luxury textiles a second life.

Crafted by Women

Every bag is handmade by skilled women artisans through ethical sewing initiatives. Slow production. Human hands. Real impact.

Unique by design

Colours and fabrics vary depending on what’s rescued. Each piece is inherently limited and unique.

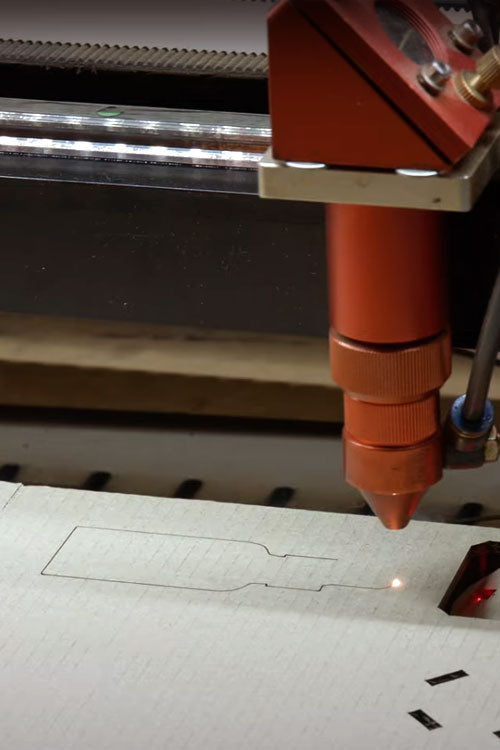

Our Upcycled Board Packaging

Packaging Waste

We collect and use packaging waste for our products

Laser Cut Board

Our designs are laser cut from this packaging waste

A Work of Art

Our final packaged products in their outer boxes